How to connect wires safely when performing, renovating or repairing electrical installations and is the Ideal Quick Wire Connector suitable for this?

In the electrical installation, wires can be connected in several ways, but in practice, apart from a few niche solutions, the choice is quite simple and is limited to screw connectors or quick connectors. But whereas screw connections require periodic checks, in the quick connector the spring is responsible for the correct connection. So, what is the problem with the former? Is it not enough to tighten the screws firmly? Many electricians tighten the screw as much as possible and forget about them (after all, they have been doing it this way for years). They fail to consider what affects the connection during, for example, a short circuit (I described the values of electromagnetic forces in the article: Effects of a short circuit). Also they do not take into account that the composition of the metal from which the wires are made has changed over the years. We commonly say that the cores of cables used in residential construction are copper, but this is a gross simplification. In practice, the conductors are made of different copper alloys, which means that they have different hardness (the issue is described in the article: Conductor diameter: Are we cheated on the quality of cables and wires?). The wire is pressed to the connector (usually brass) by a steel screw, which means that we have three metals, each with different hardness and thermal expansion. If the number of devices connected to the mains is growing, it turns out that the currents flowing through the wires for a long time are high in relation to the wire cross-section, and if the current flows through the wires, it must also flow through the connections (screw or spring). In short, the connection heats up, cools down, deforms and after some time minimal clearances appear, which in turn cause an increase in resistance, the connection heats up even more, the process is repeated and even greater clearances are formed, until sparks finally occur.

Inspection of screw connections

In Poland, there are industry recommendations according to which all screw connections should be checked every 6 months, i.e. check with a torque screwdriver whether the connection has not become loose. If the manufacturer has not provided the force with which the screw clamp should be tightened on its product, the provisions of the EN 60998-2-1:2004 standard should be used as guidelines, which specifies the tightening torque for the thread (information from the manufacturer – Simet).

| Metric thread size | Tightening torque | Screw diameter |

| M2,5 | 0,4 Nm | 2,42 mm |

| M3 | 0,6 Nm | 2,92 mm |

| M4 | 1,2 Nm | 3,9 mm |

| M5 | 2 Nm | 4,9 mm |

| M6 | 3,5 Nm | 5,88 mm |

| M8 | 4 Nm | 7,86 mm |

Source: Quick connector, screw connector or maybe a coupler? GUIDE part 3

From this point on, it is close to burning and/or catching fire. This is why it is necessary to tighten the screws with appropriate force (which is only possible using a torque screwdriver) because only then is it possible to compensate for the thermal expansion of the clamp. An alternative is to use quick wire connectors where the connection pressure is regulated by a spring. Thanks to this, the connection is constantly working and there is no need to separately control the pressure force (the manufacturer of the quick connector is responsible for the connection). For this reason, I have been using spring connections, i.e. quick connectors, for many years now.

What is important in a quick connector?

While preparing for the article, I started wondering what really matters in a quick connector. What to check and what parameters to compare? In my opinion, from the installer’s point of view, the most important things are:

- convenient insertion of the conductor into the quick connector,

- good connection quality (so that the connection does not get hot),

- good quality insulation of the quick connector housing,

- no sharp edges that may injure hands or damage the insulation of adjacent wires,

- peace of mind guaranteed by appropriate approvals, certificates and compliance with the requirements of relevant standards.

Is the Ideal Wire Connector a good choice?

I have been using quick connectors from a leading manufacturer for years, but I was asked to check and give an honest opinion about the Ideal Quick Wire Connectors offered by Simet. Since I have freedom of expression and the manufacturer does not influence my opinion apart from ordering the tests, I can carry out the tests.

I started by collecting some information about Ideal Quick Wire Connectors and already at this stage I was quite surprised. It turned out that the quick connectors offered by Simet under the brand name „Ideal Wire Connector” are produced by Ideal Industries – an American company that has been providing cable connection solutions for 100 years..

Brief description of the Ideal Quick Connectors from Simet

The SCP series Ideal Wire Connector

The SCL series Ideal Wire Connector

The SCS series Ideal Wire Connector

Interestingly, I received information that the connection method used in the SCS quick connector has been patented for about 15 years (since 2009), and the SCS2 connector itself has been available on the American market for 13 years now.

All quick wire connectors from Simet offered in the Ideal Wire Connector series have transparent housings that enable visual inspection of the connection. I am surprised by the SCL series lever wire connectors. While visually comparing the SCL wire connector with another branded wire connector, I instinctively started having fun by clicking the levers. I do not know how many clicks I made (a lot) and the levers in both connectors still work well (I cannot explain it, but I did not expect it from SCL so it is a very nice surprise).

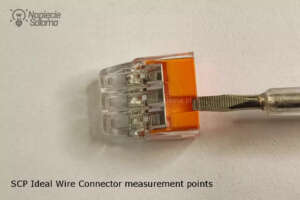

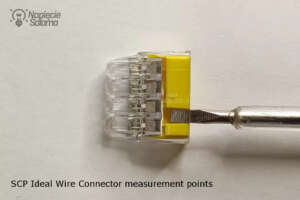

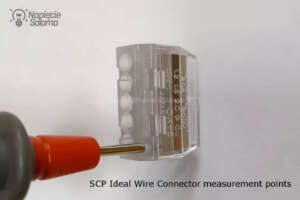

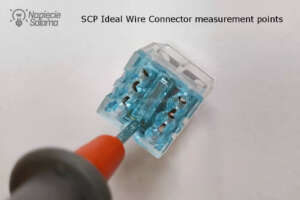

At the same time, I was surprised that the voltage measurement holes were not according to a single standard:

- SCP: 2; 3; 4 has a rectangular hole with approximate dimensions of 2.8 x 2.1 mm (the hole is too small to insert a voltage test screwdriver, but sufficient to insert the tip of a multimeter). Only after a while I realised that I had been looking for a possibility to check voltage with a screwdriver tester only to take photos because, like most installers, I have been using non-contact voltage indicators for years. Why? Because it is easier, safer, and the screwdriver tester was useful when connections were made with screw connectors, but now, when most people use quick connectors, habits and voltage indicators are changing.

- SCP: 5; 6; 8; has a round hole with a diameter of approximately 1.9 mm

- SCL: 2; 3; 5; has two rectangular measurement holes with approximate dimensions: 3 x 1.9 mm and 4 x 2 mm

- The SCS has two rectangular holes with approximate dimensions of 3.1 x 2.2 mm

| SCS2 in-line IDEAL Wire Connector for solid and stranded wires 4mm² 32A 450V |

|

The maximum sustained load on Ideal Quick Connectors from Simet is 24 or 32 A. Is that a lot? In residential installations, socket circuits are most often made using a wire with a cross-section of 2.5 mm2 and protected with a 16 A circuit breaker, while in e.g. oven or induction hob circuits, wires with a cross-section of 4 mm2 are used, most often protected with a 20 A circuit breaker. Therefore, the Ideal Wire Connectors from Simet used in residential installations should never be subjected to maximum load. Of course, in special cases, the designer may select different protection values in relation to the cable cross-section, but the role of the electrician is to appropriately select connecting elements, e.g. wire connectors, that will meet the requirements. For your convenience, here is a table of wire loads based on data from the Telefonika Kable catalogue:

| Current carrying capacity of YDYp, YDYp cables żo 450/750 V according to DIN VDE 0298 part 4 cable core temperature 70 oC. Ambient temperature 30 oC. | ||||||||||||

| Installation method | Multi-core installation cable in a sheath in an electrical installation pipe in a thermally insulated wall | Multi-core installation cable in a sheath in an electrical installation pipe on the wall | Single or multi-core sheathed installation cable laid on the wall | Multi-core installation cable in a sheath with a minimum distance of 0.3 x diameter d from the wall | ||||||||

|  |  |  |  |  |  |  |  |  |  |  | |

| Number of loaded cores | 2 | 3 | 5 | 2 | 3 | 5 | 2 | 3 | 5 | 2 | 3 | 5 |

| Nominal core cross-section | Current carrying capacity in A | |||||||||||

| 1,5 mm2 | 15,5 A | 13,0 A | 9,8 A | 16,5 A | 15,0 A | 11,3 A | 19,5 A | 17,5 A | 13,1 A | 22,0 A | 18,5 A | 13,9 A |

| 2,5 mm2 | 18,5 A | 17,5 A | 13,1 A | 23,0 A | 20,0 A | 15,0 A | 27,0 A | 24,0 A | 18,0 A | 30,0 A | 25,0 A | 18,8 A |

| 4 mm2 | 25,0 A | 23,0 A | 17,3 A | 30,0 A | 27,0 A | 20,3 A | 36,0 A | 32,0 A | 24,0 A | 40,0 A | 34,0 A | 25,5 A |

But how do I know that the Ideal Wire Connector from Simet will withstand the declared currents?

Ideal Wire Connector from Simet – check

One could argue for a long time, but in practice the installer can only subjectively assess how the cable core is inserted into the quick connector, how the quick connector „feels in the hand” and a general subjective assessment of whether such a quick connector suits a given installer or not. It is impossible to check the remaining parameters on your own without specialist knowledge and appropriate devices. What remains is trust in independent institutions that have experience and the ability to conduct specialised tests.

I will not conduct specialised tests myself, but I will check who confirms the quality of Ideal Wire Connectors. On the packaging, Simet has placed several markings that look familiar to me, but I cannot immediately explain which ones mean what, so I decided to briefly refresh my knowledge.

| RoHS – the EU Restriction of Hazardous directive Substances has been transposed into Polish law. The aim of its introduction is to reduce the amount of hazardous substances penetrating the environment from electrical and electronic waste. |

| ENEC certificate – to obtain it, a test carried out by an independent research institute approved by the European Committee for Electrotechnical Standardisation is required. A product can only obtain ENEC if it meets all of the following criteria:

|

| The CE marking indicates that the product has been tested by the manufacturer and found to meet EU health, safety and environmental requirements. This label is required for products manufactured anywhere in the world and placed on the EU market. |

| UKCA marking, i.e. UK Conformity Assessed (United Kingdom Conformity Assessed is a mark of conformity for certain products sold in the UK. Due to the UK’s exit from the European Economic Area, the UKCA mark replaces the CE mark in England. |

| CSA standards are the Canadian equivalent of the American UL standards – an American certification system aimed at reducing the risk of fire and electric shock when using electrical and electronic products. |

| This marking specifies that only copper wires can be connected in the Ideal Wire Connector (aluminium wires must not be connected and antioxidants in any form cannot be used, e.g. pastes). |

| UL Standards are an American standard designed to reduce the risk of fire and electric shock when using electrical and electronic products. The UL Listed certification category means that the entire final product is certified. |

| Ideal wire connectors are made of halogen-free materials. |

Simet also posted information showing that Ideal Wire Connectors series: SCS2; SCP2; SCP3; SCP4; meet the requirements of the following standards: PN-EN 60998-1, PN-EN 60998-2-2, UL 486C, UL 467, while those from the series: SCP5; SCP6; SCP8; SCL2; SCL3; SCL5; meet the requirements of the following standards: PN-EN 60998-1, PN-EN 60998-2-2, UL 486C. Another important information is that they have been tested and meet the UL94 V-2 flammability standard.

I have to say I am impressed by the organisations that confirm the quality of Ideal Wire Connectors. Let’s move on to practice and answer the question:

How does the quick wire connector work?

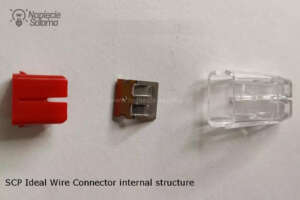

Most quick wire connectors are composed of three elements:

- outer casing

- front part with a funnel for introducing the wires of the cable

- springs

The outer casing of the quick connector should not have sharp edges and must be made of a material that is resistant to elevated temperatures and does not spread flame. The front of the quick connector has holes through which wires can be inserted into the quick connector (the copper wire is led to the spring and the cable insulation should be in the hole in the front of the quick connector). It is important that the holes introducing the wires are made in the shape of a funnel, which allows easy insertion of the wire into the spring. At the same time, the holes must be large enough for the cable core insulation to be inside the quick connector (no conductive parts of the wires can be accessible outside the quick connector). The spring is responsible for the correct connection. With its working cross-section and contact surface with the conductor, it is the most important element of every quick connector as it is crucial for the correct connection.

At the point where the wire touches the spring, a point connection is made in an oxygen-free manner. I am often asked whether, in the point connection, the contact surface is too small in relation to the current flowing through the quick connector. In reality, we do not have to deal with it because the spring designers are responsible for it and it is the responsibility of the manufacturer and the companies that tested the quick connector and issued approvals. Remember that the greatest advantage of a spring connection is the constant pressure of the spring on the cable core (which does not change over time). It is worth knowing that at the point of contact between the spring and the conductor, a point contact is created to which gases (air) have no access, thanks to which the connection point is not subject to oxidation processes, which is why it is called an anaerobic connection.

| The spring presses the wire of the cable with a constant force | The manufacturer selects the contact area between the spring and the cable conductor accordingly in relation to the expected currents |

|  |

Does this mean that the cable in the quick connector does not tarnish? The copper conductor of the cable inserted into the quick connector is exposed to aging processes that occur due to the contact of metal elements with air and the copper conductor may become tarnished over time. At the same time, the connection point between the spring and the copper wire does not oxidize, so, most importantly, the connection resistance remains unchanged. Another question worth asking is:

Why do quick connectors burn?

It is no secret that you can find photos of various burnt quick connectors (from various manufacturers) in social media, but remember that photos of burnt and/or overheated screw connections appear much more often. Why do some quick connectors burn, despite the spring connection?

There is no clear answer to this. Let us remember that regardless of the manufacturer, quick connectors are produced by machines in millions of pieces. Machine production allows us to maintain the quality and repeatability of products, and good manufacturers, including Ideal, make every effort to ensure that the quality control at the factory detects quick connectors that, for various reasons, do not meet high standards. At the same time, I would like to point out that the most common cause of quick connectors’ „burning” are errors made by installers. The manufacturer of a quick connector takes responsibility for the connection, provided that the installer correctly selects the quick connector for the environment and prepares and inserts the cable into the quick connector. Preparing the cable seems simple, so what errors do I mean?

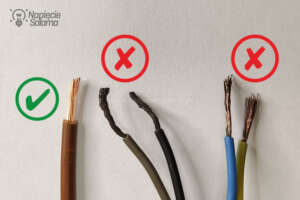

The most common mistakes

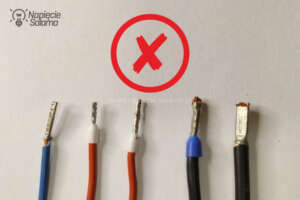

Below I have listed typical errors as far as spring connections are concerned, regardless of the manufacturer of the quick connector.

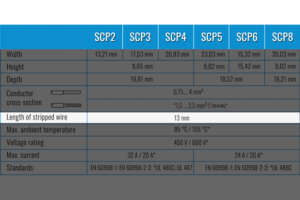

The basic error is poor cable insulation. Insulation stripped over too long a section of cable increases the risk of a short circuit or electric shock (conductive parts of the cable accessible outside the quick connector). On the other hand, insulation removed from too short a section may result in the cable core not being properly „fixed” in the quick connector, which means that the spring will not provide a proper connection. Remember that, depending on the manufacturer, the right length of the insulation must be stripped, and that may be different for different manufacturers (routine leads to errors, always check the manufacturer’s guidelines). For the Ideal Wire Connector, 13 mm of the insulation should be removed.

The exception is the SCL series Ideal Wire Connectors, where the insulation should be removed from the cable core at a length of 11 to 12 mm.

Another common mistake is introducing bent wires into the quick connector. Even a slightly bent copper wire prevents the spring from pressing the wire on the entire surface intended by the designer. In such case, the measurement of the connection resistance may work without any problems, but when higher currents begin to flow through the quick connector, the smaller than expected connection surface begins to heat up excessively, which leads to the quick connector overheating or even burning. In such a situation, damage to the quick connector is not the fault of its manufacturer.

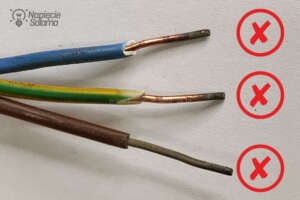

In the case of quick connectors with levers for connecting solid or stranded wires, most installers make a serious mistake. After stripping the insulation, they twist individual wires in their fingers (this is to prevent individual wires from bending and to facilitate the insertion of a stranded wire into the quick connector terminal). Why is twisting the wires a mistake? When a large number of straight wires arranged parallel to each other are introduced into the clamp, the spring compresses them over a relatively large surface. An oxygen-free connection is created between the spring and the compressed individual wires, which is able to safely conduct the currents intended by the designers. However, when the installer inserts twisted wires into the terminal, there are empty spaces between the individual wires, the actual connection has a smaller contact area than expected, which causes excessive heating and may lead to the destruction of the quick connector.

Introducing tarnished cable cores into the quick connector. Even new cables, if stored in poor conditions (especially moisture), may be suitable… for scrap. In various installations, I relatively often encounter copper cores (stranded or solid) covered with black coating. Several times I admonished installers who pressed such a „black” wire into the quick connector, or to those who tried to clean it in various ways (they scraped the wire with a knife, or even worse, tried to clean single wires in multi-wire cores in the same way). Will the installation connected this way work? Probably yes, but under the influence of current flow, the connection made in this way will heat up excessively, and in the case of higher currents it will lead to the destruction (melting) of the quick connector. In such a case, the fault for damage to the quick connector lies solely with the person who made the connection.

|  |

Can sleeved multi-wire cable cores be inserted into the quick connector? Do you remember how I discussed the internal structure of the quick connector, and in particular how the spring presses the wire? In your opinion, will the cable end sleeve provide the same large and good contact surface between the spring and the cable core? I believe such connections should be avoided. Please note that there are different types of crimping tools, but looking only at the connections made, we distinguish:

- „normal” crimping

- anaerobic crimping

In the case of „normal” crimping, individual wires are inside the end sleeve, but air also penetrates between the individual wires, which over time leads to tarnishing, increased resistance and heating of the connection. As long as the cable has been prepared correctly and the end sleeve is crimped oxygen-free, the risk of an internal increase in resistance is minimised, but the connection of the spring with the uneven surface of the sleeve remains (compare: introducing bent cable strands into the quick connector).

The quick connector is a product that must be properly stored and used. Each manufacturer specifies the conditions in which the quick connector should be stored and used. But manufacturer’s guidelines are not always followed. I could cite many examples, but I will give only one, but it is the most common: water damage. I saw containers with quick connectors that were wetted after the weekend with water, or rather with a solution of water and plaster or other chemicals (water that dripped from the plastered ceiling) because someone somewhere simply did not take care of something and it started leaking… Quick connectors that were „accidentally” washed along with the clothes. It is a pity to throw away quick connectors that are „as new”, they just need to be dried. Unfortunately, these quick connectors are no longer usable and should be thrown away. Even though they were not used, they were stored incorrectly, therefore, e.g. the spring may have a damaged protective coating and may lose its parameters over time, which will translate into an increase in the connection resistance. Higher connection resistance and high currents result in significant heat generation, which may result in melting and destruction of the quick connector.

But in the end, no one will tell you about the mistakes made (maybe they do not even know about them because someone else made them), they will just take a photo and post the damaged quick connector from one or another manufacturer on the Internet. Another question:

Does the order in which the wires are connected in the quick connector matter?

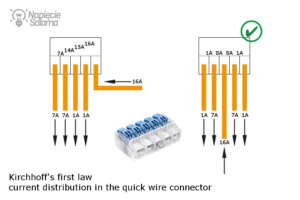

Few people wonder whether the order in which they insert the wires into the quick connector matters, and it is enough to remember the issues from physics lessons for the answer to be very simple. Let me remind you of one of the basic laws regarding electricity, which is Kirchhoff’s first law and concerns currents in a node of an electric circuit:

The sum of the currents flowing into a node is equal to the sum of the currents flowing out of it.

What does this mean in practice? Please analyse the figure below. In an electrical installation, power is most often fed into the quick connector via one wire, and the current is distributed to the remaining wires via a spring. Let’s assume that a current of 16 A flows in the power cable and on the load side we have two 7 A and two 1 A circuits.

To dispel doubts. As long as the total current flowing through the quick connector does not exceed the rated current of the quick connector, both connection methods presented in the diagram are correct, but in the system shown on the left, a current of 16 A flows through the part of the spring, which decreases with each connected wire (drain). The diagram on the right also shows the connection of the same loads, but thanks to a different order of connecting the wires, much smaller currents flow through subsequent parts of the spring. What’s the benefit? Lower current (at the same voltage) causes less heat (the quick connector heats up less), which, combined with the errors discussed, can easily result in damage to the quick connector.

Have I found an error in the documentation for Ideal Wire Connectors?

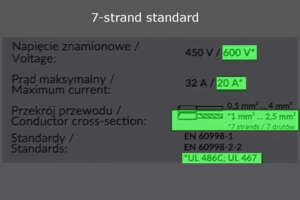

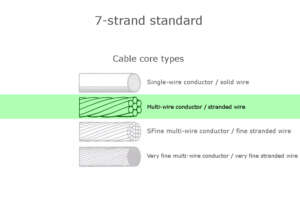

I read thoroughly the brochures, leaflets and information provided by Simet. I found the method of connecting a stranded wire in Ideal Wire Connectors without a lever rather surprising. There must have been an error.

|  |

Well, no. In the USA and in some European countries, cables with conductors made of seven strands are used (actually, I knew about it, but while reading I focused on Polish standards). These conductors are so stiff that they can be pressed into SCS2 series wire connectors (cross-sections from 1 to 2.5 mm2) and SCP series quick connectors SCP2; SCP3; SCP4; SCP5; SCP6; SCP8 (core cross-sections from 1.5 to 2.5 mm2). Finally, the question is, in what conditions can Ideal Wire Connectors be used? According to the manufacturer’s recommendations, they should be used in dry places that are not normally exposed to moisture or the risk of getting wet. Places classified as dry may be temporarily exposed to damp or wet conditions, as in a building under construction. The last question is:

Finally, the question is, in what conditions can Ideal Wire Connectors be used? According to the manufacturer’s recommendations, they should be used in dry places that are not normally exposed to moisture or the risk of getting wet. Places classified as dry may be temporarily exposed to damp or wet conditions, as in a building under construction. The last question is:

Is the Ideal Wire Connector disposable?

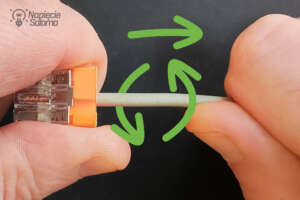

NO. The ideal SCL series quick connectors (with lever) allow easy cable replacement by lifting the lever. The single-wire cable can be removed from the SCP and SCS series push-in quick connectors as from other brand quick connectors. To do this, pull the cable out of the quick connector while making a rotary movement. After several repetitions, the solid wire is removed from the Ideal Wire Connector.

| Pulling out the cable core from the quick connector | The single-wire conductor after being removed from the quick connector has characteristic spring marks |

|  |

It was supposed to be a short introduction to the Ideal Wire Connector, but it turned out as always

Summary of Ideal Wire Connectors

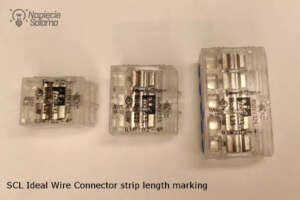

The Ideal Wire Connectors of the SCP and SCS series lack a „gauge”, i.e. marking of the length of the stripped cable core. However, the Ideal Wire Connectors of the SCL series have this feature, but in my opinion, it is not clearly visible (I only noticed it in the photos).

Is this a defect that disqualifies these quick connectors? No, it is just my habit, and because neither in Ideal Wire Connectors from Simet nor in the documentation presented did I find anything that would arouse my distrust, I will add them to my handy toolbox and I use them. At the same time, I will observe them in my installation and, since I have large and frequently switched on loads, they will undergo a thorough practical test. If you want to try Ideal Wire Connectors, use the contact form on the website www.idealnaszybkozlaczka.pl, where you can order free product samples.

Download the information leaflet of Ideal Wire Connectors from Simet in PDF format >>

Remember (regardless of the manufacturer), the use of quick connectors does not release you from the obligation to reliably carry out mandatory regular inspections of electrical systems, which include, among others: visual inspection and measurements. A comprehensive inspection of the installation should be performed at least every 5 years.